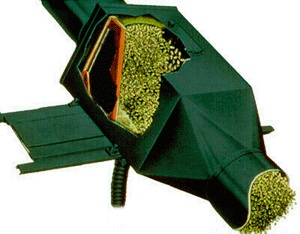

Grain samples to be inspected are collected by a Diverter-Type (D/T) Sampler, which is located either before or after the scale. Once every sampling interval (usually set between 12 and 25 seconds) a motor sweeps a sampling container called a pelican through the grain stream.

A pipe coming out the bottom of the pelican drops the grain sample into a collecting funnel. It then flows through a pipe to the inspection lab, where it is graded. A secondary sampler (not shown) divides the sample between the Federal inspection lab and the elevator's quality control lab.

Related topics

- Operation of an Export Elevator

- Operation of a Bulk Weighing Scale

- Electronic Monitoring and Control Systems

- Testing a Bulk Weighing Scale

- Virtual Reality Models